LEV Testing

At Purex, our team of P601 and P602 accredited engineers deliver LEV tests across a comprehensive range of LEV systems. Book yours today to guarantee peak performance and COSHH compliance.

LEV Test Process

1. Examination

An LEV Test is compiled of a series of visual, technical and maintenance checks, including but not limited to:

- A visual examination of the entire system is performed to check for mechanical integrity and cleanliness and ensure there is no damage, corrosion, or blockages.

- A detailed inspection of all components, including ducts, hoods, filters, and fans, to ensure each element is operating as intended.

- Airflow measurements to ensure the system is capturing and transporting contaminants effectively and meeting target velocities.

- Control system checks to ensure sensors are working as intended and alarms are triggering correctly if the system isn’t operating optimally.

2. Reporting

After the test, our LEV engineers provide a comprehensive report detailing essential measurements and observations, such as velocity and pressure readings. The report also identifies any faults and includes a certificate indicating whether your LEV system is safe to use.

3. Remedial Work

If your LEV system fails the test, immediate corrective actions are necessary to ensure compliance with HSE standards. These actions can range from minor adjustments to replacing components or, in extreme cases, the entire system. Regular LEV servicing and maintenance can help your system pass the annual LEV test without issues.

LEV Testing Frequency

According to COSHH Regulation 9, a performance and safety test should be conducted at least every 14 months. However, for systems used regularly, more frequent maintenance checks are advisable, as regular servicing ensures your system remains safe and compliant year-round.

Recent changes to HSE guidance mean new LEV systems must now be commissioned before use. For more information, visit our LEV Installation page.

Importance of LEV Testing

LEV testing is not just a regulatory requirement but a crucial step in maintaining a safe working environment. If your LEV system is not working effectively, it can cause serious health issues, including, but not limited to:

- Asthma

- Chronic Obstructive Pulmonary Disease (COPD)

- Acute pneumonia

- Asphyxiation

- Lung cancer

In turn, employers are legally obligated to regularly test their fume extraction systems under COSHH Regulation 9 to ensure they’re operating efficiently. Failure to do so will mean their systems will not be HSE compliant, and their health insurance will be void against cases regarding faulty or ineffective extraction. Therefore, it’s vital to schedule regular LEV tests to safeguard employee health and well-being.

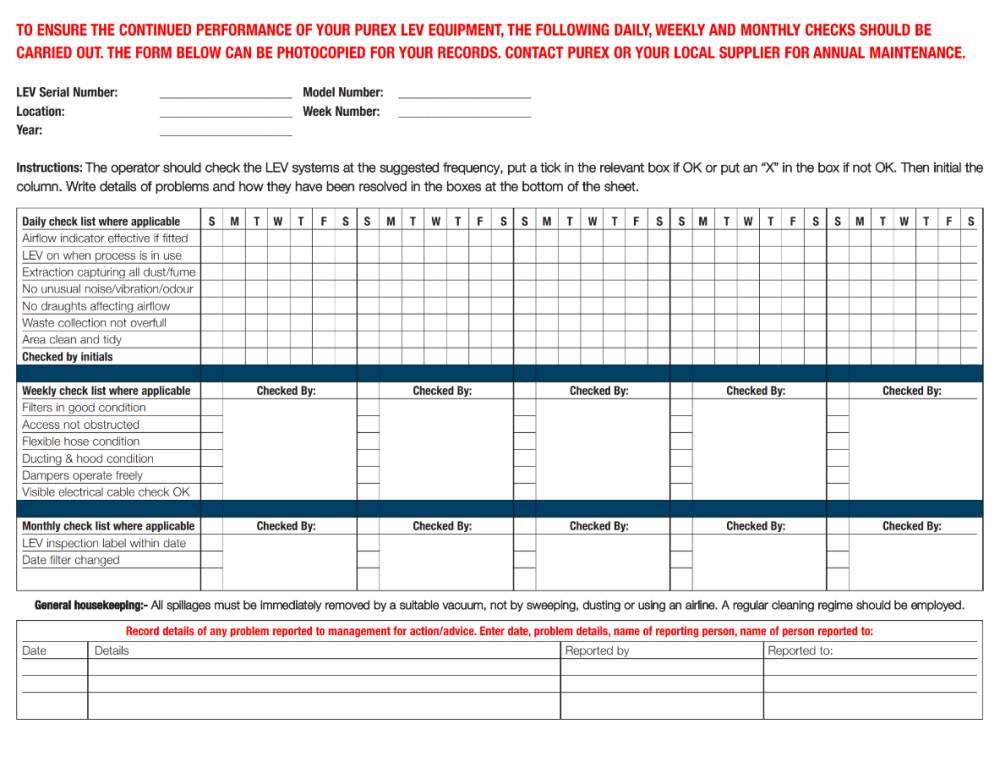

LEV Log Book

Following your LEV test, it’s important to update your LEV log book. All LEV systems are required to keep a log book that includes:

- Schedules for servicing and maintenance

- Records of any services, replacements, and repairs made to your LEV system

If you have any questions about your LEV system, log book or our services, please contact our team. We have a technical helpline, so we support you daily with the maintenance of your machine.

Why Choose Purex?

With over 40 years of industry experience and a steadfast commitment to our customers, we are your premium choice for all fume extraction and LEV needs.

- Expertise and Accreditation: Our qualified LEV engineers are dedicated to delivering exceptional LEV services. By undergoing rigorous testing, we can ensure your LEV system will be COSHH-compliant and operating optimally.

- Customer Commitment: We pride ourselves on our customer service. From your initial consultation to your annual test, we are with you every step of the way.

- Proven Track Record: Our extensive portfolio of satisfied clients speaks for itself. We invite you to review our case studies to see the quality of our work.

What’s more, our LEV services aren’t limited to Purex machines – we can test any LEV system, making us your first choice for all fume extraction and LEV requirements.

Don't just take our word for it…

Purex carried out the work swiftly with minimal disruption to the production team

FAQs

Your LEV system must be tested at least once every 14 months. However, we recommend scheduling an LEV test at least once a year to guarantee consistent performance and compliance.

The duration of an LEV test depends on a variety of factors, including:

- The number of systems being tested

- The complexity of the system(s)

- The condition of the system(s)

- The accessibility of the system(s) and related parts

For example, a standard single arm extraction system can take as little as 1-2 hours to test, whilst complex systems with multiple accessories and components can take over a day to fully assess.

If your system fails its LEV test, we will outline the necessary remedial works needed to restore your system to good working order within your report. However, in the rare instance your LEV system is condemned, we can help you find a suitable alternative based on your unique business requirements.

Yes, it is a legal requirement to test your LEV system at least once every 14 months. Failure to do so can result in fines and prosecution under the Health and Safety at Work Act 1974, invalid insurance against liability claims and the retraction of compliance certifications.

There are a series of benefits to regularly testing your LEV system, including but not limited to

- Assuring employee health and safety

- Improving operational and cost efficiency

- Preventing unexpected downtime or repairs

- Assuring legal compliance

Book your LEV Test

At Purex, we offer LEV tests for a wide variety of LEV systems - not just Purex products! Enquire today for a comprehensive LEV test.

-

Unit A, Saltgrounds Road,

Brough, East Riding of Yorkshire,

United Kingdom,

HU15 1EG - +44 (0) 1405 746030

- purex@purex.co.uk