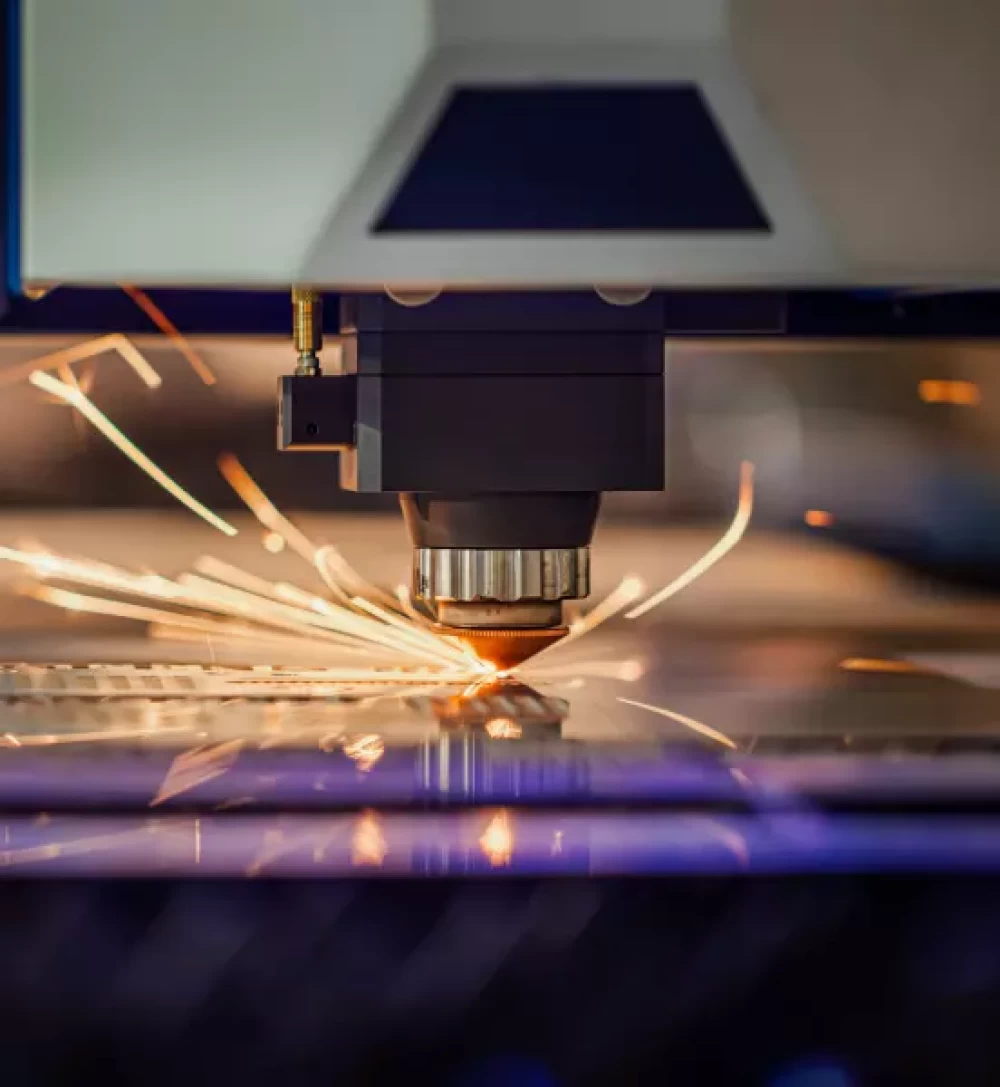

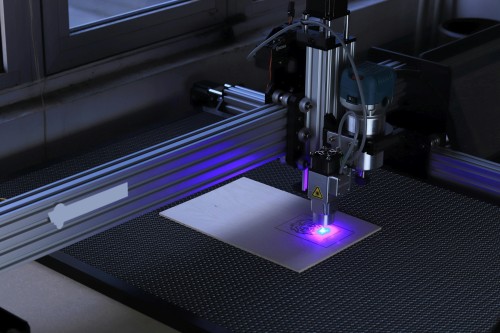

Fume Extraction For The Laser Industry

Industries involved in laser marking and coding burn or vaporise the surface of materials, creating harmful particles and vapours. Without an efficient fume extraction system in place, these contaminants can damage laser equipment and significantly impact the health of employees. It’s crucial to have a reliable system to ensure a safe and clean working environment.

Burning or vaporising materials creates harmful particles and vapours, which can both damage your laser equipment and significantly impact the health of your employees. At Purex, our extensive range of laser fume extractors are designed to combat hazardous Laser Generated Air Contaminants (LGAC’s), across a variety of processes, to provide a safe and efficient working environment.

Typical applications

Marking & Coding Applications

Marking and coding applications use a laser to burn or vaporising the surface of a material to create permanent legible markings, often a date or serial number. This creates harmful particle and vapours depending on the base material being marked or coded. Purex offer a wide range of laser extraction so that regardless of the amount of codes or marks your system is capable of performing we have a extraction unit to suit.

Engraving Applications

Similarly to marking and coding, laser engraving involves vaporising materials to create permanent markings. However, laser engravings create significantly deeper grooves than surface-level markings. In turn, the volume of vapourised material and hazardous fumes also increases. Purex offer a wide range of laser extraction so that regardless of the materials being engraved of the size the laser system we have a extraction unit to suit.

PVC Applications

When a laser burns or vaporises PVC it produce's highly toxic fumes, including hydrochloric acid. Hydrochloric acid is extremely corrosive to steel, and can corrode the extraction unit. However, our PVC units are designed to prevent corrosion to the machine. They are Epoxy coated and have all internal parts made from non-corrosive materials. They are also have specialist filters installed to purify these dangerous gas’s.

Recommended machines

-

200i

200i

200i

The Purex 200i with its main filters and labyrinth pre-filter efficiently eliminates harmful particles from your workplace.

View product -

FumeCube Max

FumeCube Max

FumeCube Max

The Purex FumeCube Max is a compact, versatile fume extraction solution. With its Labyrinth pre-filter its designed for electronics production, light laser coding and marking. This machine features an LED varicoloured filter status indicator, which uses a traffic light system to inform operators about the status of the filters. It also has an Automatic electronic flow control - maintaining a constant extraction rate even as the filter blocks, ensuring high performance without any loss of efficiency. Available with multiple connection kits to suit your application.

View product -

Lasersafe

The Purex Lasersafe is an affordable solution, with its compact size the machine can be effortlessly relocated. This makes the machine a cost effective choice designed to maintain a consistent extraction rate and decreased down time.

View product -

iFume Range

The Purex iFume range is our versatile and efficient solution, designed to cater for a wide range of applications. These variable range of units are an ideal tailored solution that aligns with your specific requirements. Guaranteed to provide employee safety and efficiency.

View product -

400i

400i

400i

This versatile machine is commonly used in the Laser Engraving and Coding industry, its high extraction rate and compact size make it renown around the world

View product -

400i PVC

400i PVC

400i PVC

The Purex 400i PVC - Designed to tackle harmful corrosive contaminants produced by laser marking PVC parts, Purex PVC units are specially coated to prevent corrosion on the internal surfaces.

View product -

300i

The Purex 300i is designed to ensure safety, its compact size allows it to be used in a variety of industry's while taking up less workspace.

View product -

PUR35 Range

The Purex PUR35 is a compact, high-performance, and cost-efficient unit. It’s easily relocated, simple to install, and ensures operator safety.

View product -

PUR35

PUR35

PUR35

The Purex PUR35, our top-tier and economically viable solution, is equipped with a total of three filters - two primary ones and an additional pre-filter. Its design emphasizes portability and ease of installation, thanks to its compact dimensions. This makes the PUR35 an ideal choice for those seeking a flexible and efficient filtration solution.

View product -

PUR35 Chemical

PUR35 Chemical

PUR35 Chemical

This versatile device prioritises operator safety and adaptability. Its unique split filter design contributes to a cost-effective ownership experience. Please note that the chemical variant of the PUR35 is equipped with a single primary main filter. This information is crucial for potential owners to understand the maintenance requirements of this model.

View product -

Alpha 400

The Purex Alpha 400 is a cost-effective, easy-to-install solution for your specific laser fume extraction operations. It features an LED warning system and would be an ideal choice for the Laser industries.

View product -

Base Unit Range

The Purex Base units are a bench type fume extraction system that safeguards your workspace from harmful pollutants. It’s a preferred choice in the laser industry, especially for intensive laser engraving and cutting filtration.

View product -

Ebase

Ebase

Ebase

The Purex Ebase Fume Extraction System reliably maintains a clean and safe working environment by effectively eliminating harmful contaminants. Its low-profile design allows a laser engraving device to be placed on top, reducing the overall footprint, or it can be positioned under pre-existing work benches. Renowned in the Laser Industry, the Ebase fume extractor is particularly recommended for heavy-duty tasks like laser engraving and cutting.

View product -

Xbase

Xbase

XBase

The Purex Xbase Fume Extraction System ensures a clean and safe working environment by efficiently removing harmful contaminants. Its compact design allows a laser engraving device to be placed on top, minimising the required space, or it can fit under existing work benches. Well-regarded in the Laser Industry, the Xbase fume extractor is especially recommended for laser engraving and cutting tasks.

View product -

Purex Pulse Jet

Purex’s patent pending Pulse Jet filtration technology is engineered to extend filter life, minimize downtime, and provide cost-effective solutions.

View product -

750 Range

The Purex 750 range is a high-performance unit and with automatic electronic flow control it ensures smooth operation. The series offers the 750 2-Tier and 750 3-Tier models, catering to diverse needs.

View product -

800i 2 Tier

800i 2 Tier

800i 2 Tier

The 800i 2 Tier – Equipped with one primary and one labyrinth pre filter, this unit is highly efficient for extraction from gases and chemicals, making it an excellent solution throughout various industry's.

View product -

1750i Range

The Purex 1750i 3 Phase unit is a robust, high-performance machine designed for high gas-emitting applications. It offers precision, easy filter change, adjustable airflow, and low operational costs.

View product -

1750i

1750i

1750i

The 1750i 3 Phase - Would be a reliable solution designed to eradicate heavy-duty odours from Laser Marking and Engraving on various materials such as plastics including acrylic.

View product -

2000i

The Purex 2000i 3 Phase is a cost-efficient and reliable solution, offering adjustable airflow and low operational costs. Its easy installation, portability, and precision operation make it a robust and high-performing asset for your needs.

View product -

5000i Range

The Purex 5000i range 3 Phase units are designed to effectively and efficiently remove a large volume of hazardous fumes. The versatility of the 5000i range is further enhanced by its specialized units, including the 5000i HD 3 Phase and the 5000i PVC 3 Phase.

View product -

5000i HD

5000i HD

5000i HD

The Purex 5000i HD (heavy duty) 3 Phase, has been expertly engineered to eliminate hazardous pollutants from your work environment, ensuring a safer and healthier workspace. It comes equipped with two pleated pack pre-filters to allow it capture high dust producing laser particles, for example, Laser Cutting labels.

View product -

5000i

5000i

5000i

The 5000i 3 Phase offers a choice of pre-filters depending on if your workspace allows side inlet or rear inlet. This machine is able to extract from up to 36 separate Purex arm kits simultaneously, making it an ideal choice for large scale Hand Soldering processes. Its large air flow also allows it be used for Wave Soldering applications where a steady and constant airflow is needed. In addition, it can be used on large scale Laser Engraving and Coding processes.

View product

Case Study

Laser Engraving

As the use of laser engravers for personalizing patterns and text on various materials continues to grow, ensuring proper air filtration has become increasingly critical. Discover why air filtration is essential and what Purex can offer to enhance your laser engraving operations.

Industry Insights

-

Why Graphtec GB’s Laser Cutter Needs an Purex Extraction & Filtration System

If you’re using a CO₂ laser cutter or engraver - whether in a school, workshop, or studio- there’s one piece of equipment you... Read more -

How Does A Laser Cutter Fume Extractor Work?

Where are you right now, and what can you see around you? Perhaps you can see a lamp, table and chairs – or maybe you can spot jewellery, tools... Read more -

Guide To LEV Testing

If your business uses a fume extraction system, you’ve probably heard of an LEV test. But what exactly does LEV actually stand for, and what is... Read more

Need help choosing?

Speak to a member of our expert team to help choose the most suitable machine for your requirements.