Insights

Stay informed with the latest news and insights directly from our industry leaders. This section provides you with thought-provoking articles, in-depth analyses, and visionary perspectives that reflect the expertise and innovative thinking of our leading professionals.

-

Purex International Ltd Bids Farewell To Its Former Headquarters

Today marks the end of an era for Purex International Ltd. After years of innovation, collaboration, and growth within these walls, we say goodbye to... Read more -

The Role of Spark Arrestors in Fume Extraction Systems

When working with fume extraction systems, safety isn’t just about filtering out harmful fumes; it’s also about fire prevention. One key f... Read more -

How Regular LEV Servicing Prevents Health Hazards

You might not think it, but regular LEV maintenance is a very important aspect in safeguarding for the health and safety of workers in environments wh... Read more -

The Dangers of Ozone Fume Inhalation

While ozone in the atmosphere protects us from the sun's ultraviolet rays, at ground level, it becomes a harmful pollutant with far-reaching effects o... Read more -

New HSE LEV Commissioning Rules 2025 – Stay Compliant with Purex

The Health & Safety Executive (HSE) has quietly raised the bar. On 28 March 2025, it published a brand-new guidance page, “Commission your l... Read more -

How Fume Extraction Improves Workplace Health and Safety

We all know that health and safety is paramount in the workplace. But how do fume extraction systems improve this? In our guide, we’ll explain h... Read more -

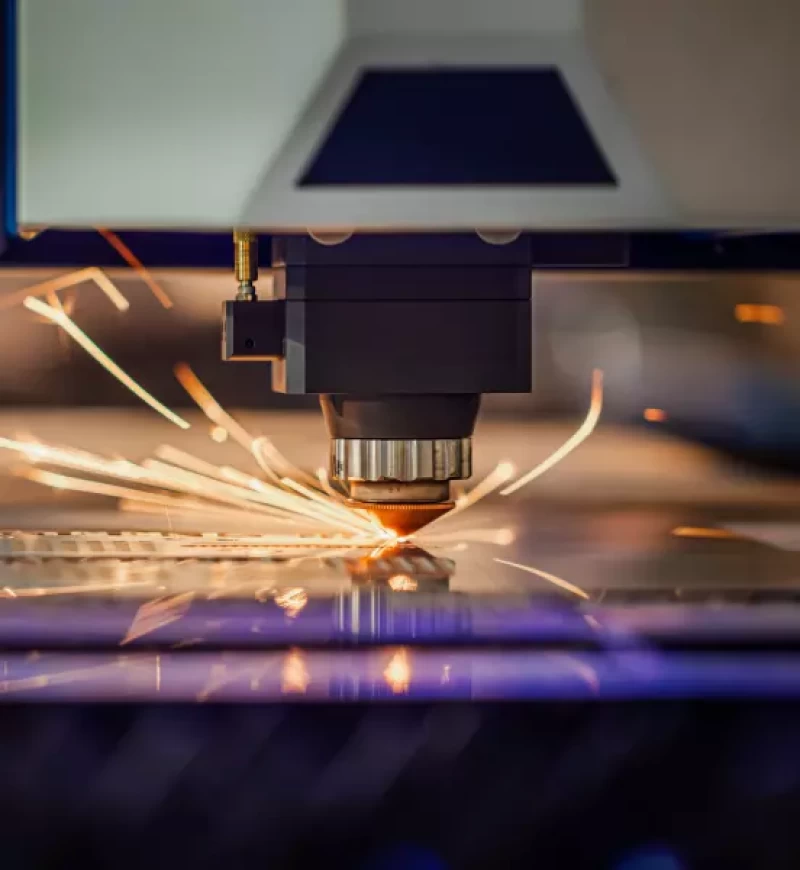

How Does A Laser Cutter Fume Extractor Work?

Where are you right now, and what can you see around you? Perhaps you can see a lamp, table and chairs – or maybe you can spot jewellery, tools... Read more -

Protecting Welders from Harmful Fumes

Designed to fuse materials, welding is a fundamental process in manufacturing and engineering industries. However, welding can also expose workers to... Read more -

Celebrating 40 Years of Innovation at Purex

This year, Purex proudly celebrates a monumental milestone: 40 years in business. From our humble beginnings to becoming a global leading company, o... Read more -

The Dangers Of Silica Dust

What is silica dust? Silica dust, or Respirable Crystalline Silica (RCS), is a natural substance in stone dust. Present in various types of rock incl... Read more -

How Purex is Committed to a Greener Future

At Purex, we believe that a greener future is not just a goal - it's a responsibility. As leaders in the clean air industry, we are dedicated to imple... Read more -

Guide To LEV Testing

If your business uses a fume extraction system, you’ve probably heard of an LEV test. But what exactly does LEV actually stand for, and what is... Read more