Fume Extraction for the Additive Manufacturing Industry

Purex machines are reliable for use in the Additive Manufacturing industry. This industry involves the industrial creation of three-dimensional objects by adding material layers. A 3D model is designed, and it creates intricate objects that can be made large or small. These processes are primarily produced using CAD models or 3D printing applications.

From small-scale businesses to global corporations, countless businesses are harnessing the power of Additive Manufacturing to and enhance their manufacturing processes. At Purex, our fume extraction systems efficiently extract toxic fumes, ABS filament fumes, vapours and ultra-fine particles to protect operators from harmful byproducts produced during the 3D printing process. Learn how our fume extractors can support your additive manufacturing processes:

Typical applications

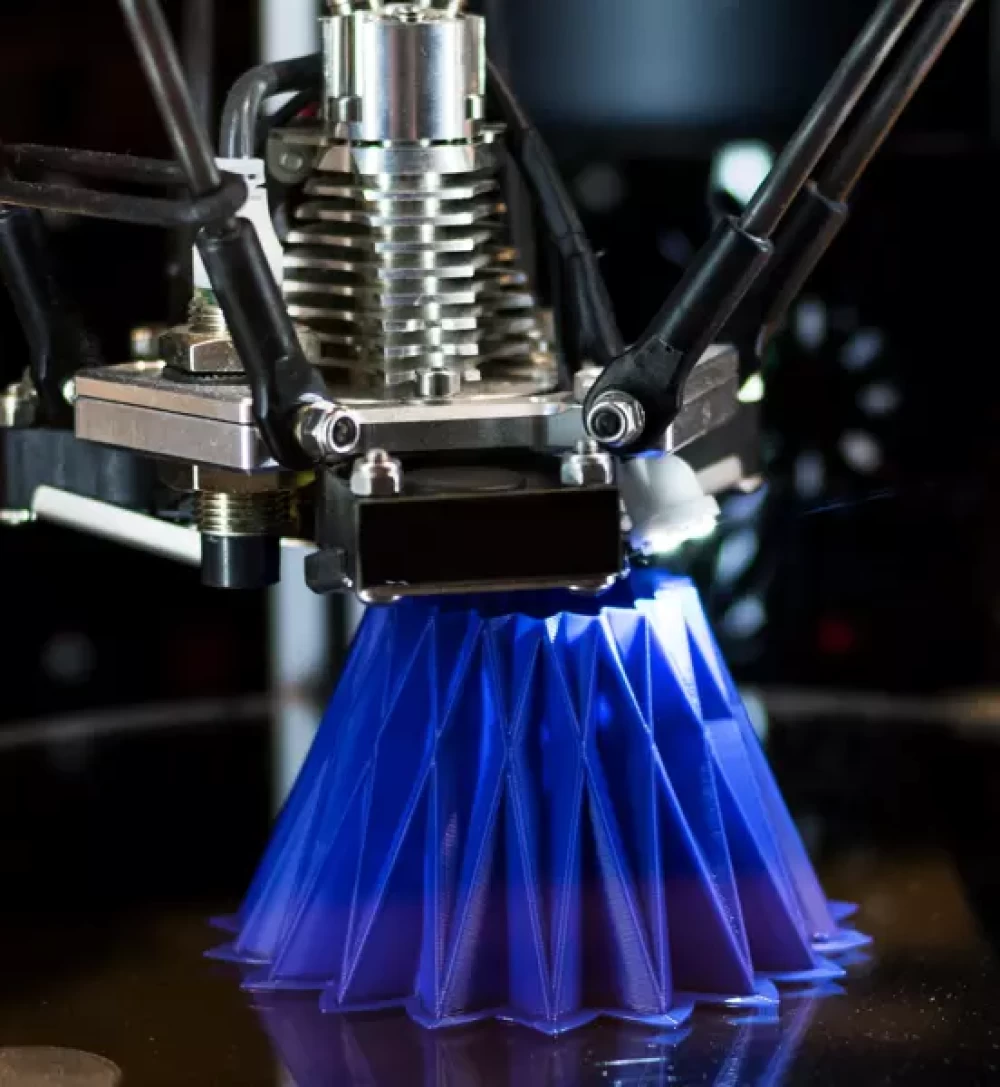

3D Printing

3D printing has applications across various industries, including Aerospace, Automotive and medicine. However, the 3D printing process can release harmful elements such as volatile organic compounds (VOCs) and ultrafine particles. Exposure to these fumes may result in respiratory issues, inflammation of the eyes, nose, and throat, and even pose a potential risk of cancer. Luckily, our Purex machines are designed to avoid these health risks. By efficiently eliminating harmful particles and ensuring clean air, they contribute to a safer working environment for those involved in 3D printing.

Fused Deposition Modelling (FDM)

Fume Deposition Modelling is the most commonly used 3D printing process. It involves melting a thermoplastic filament and extruding it layer by layer. As a result, FDM produces ultrafine particles and volatile organic compounds (VOCs). Inhalation of these toxic byproducts can cause:

- Respiratory issues caused by lung inflammation

- Nausea, fatigue and headaches

- Increased exposure to carcinogens

Our fume deposition extraction systems are designed to extract toxic fumes and particles to ensure operational safety, without compromising the FDM production process.

Selective Laser Sintering (SLS)

SLS systems create parts via a CO2 laser that selectively sinters and fuses thermoplastic polymer granules. Like FDM, SLS creates ultrafine particles and depending on the granules other dangerous particles can be expelled into the workplace. While generally more expensive than FDM, SLS can create better-resolution parts with excellent mechanical properties and intricate geometries while remaining accurate. Inhalation of these toxic byproducts can cause:

- Respiratory issues caused by lung inflammation

- Nausea, fatigue and headaches

- Increased exposure to carcinogen

Our selective laser sintering systems and designed to enhance the SLS process and protect the equipment and users from any dangerous particles.

Digital Light Processing

Digital Light Processing utilises a digital light projector to cure liquid resin, creating detailed models and casts quickly and efficiently. However, the fumes produced when curing the liquid resin is highly hazardous and can cause:

- Dizziness, headaches and throat irritation

- Increased risk of cancer

Our DLP fume extractors are designed to extract these toxic fumes to protect your operators, without hindering the DLP process.

Recommended machines

-

400

400

400

The 400 is a versatile machine for use within the Electronics industries due to its small footprint and powerful air flow abilities.

View product -

Cub3d

The Purex Cub3d is both a cost-effective and high-performing unit. This unit has been specifically designed to cater to the unique demands of the 3D printing industry.

View product -

800 Range

The Purex 800 range are advanced, automated extraction units, designed to provide superior protection for your operations. Each unit is precise, powerful, and ensures high performance.

View product

Case Study

Additive Manufacturing

Purex have been supplying extraction units to along with Stratasys H350 3D printer, in this case study we examine a install we carried out and look at why the Purex unit was used and how it has helped the company.

Industry Insights

-

The Dangers of ABS Filament Fumes

What is ABS filament? ABS, also known as acrylonitrile butadiene styrene, is a thermoplastic filament that allows you to print durable 3D parts that... Read more -

Are Nylon Filament Fumes Harmful?

What are nylon filament fumes? Nylon is most commonly used in industrial 3D printing, usually associated with plastics, though it can also be fo... Read more -

End of Year Statement 2023

To The End of 2023 With over three decades of manufacturing high quality and effective fume extraction systems under our belt, we are pleased to anno... Read more

Need help choosing?

Speak to a member of our expert team to help choose the most suitable machine for your requirements.