The Dangers of ABS Filament Fumes

3D printing has transformed how industries create prototypes, parts, and designs. But while it’s an exciting technology, it also comes with hidden risks, especially when using ABS (Acrylonitrile Butadiene Styrene) filament.

Have you ever noticed the strong smell released while printing with ABS? That odour is more than unpleasant; it’s a sign that potentially harmful fumes and ultrafine particles (UFPs) are being released into the air. Without the right protection, exposure can put both health and workplace safety at risk.

What is ABS filament?

ABS, also known as acrylonitrile butadiene styrene, is a thermoplastic filament that allows you to print durable 3D parts that can withstand plenty of wear and usage. It is a stiff 3D material that is impact and heat-resistant. In a raw form, ABS material is white in colour.

The neutral colouration can be easily dyed during the manufacturing process to your desired colour. Common uses for ABS include manufacturing materials which are built to withstand high mechanical stress, moving parts and end-use tools.

Are ABS filament fumes toxic?

Although ABS filament fumes are not considered toxic, they are unpleasant to experience. As the material is heated in a 3D printer, it creates gas and microscopic particles during the process. These fumes can cause physical discomfort such as drowsiness, eye irritation, nausea, and headaches.

It’s also important to note that the fumes from plastic are often carcinogenic and can cause acute irritation to the respiratory system. If material is processed under prolonged exposure to high temperature or flame, thermal burns to the skin can occur.

What industries are most at risk from ABS fumes?

- Additive Manufacturing – ABS is a staple in prototyping and 3D object creation. Without extraction, operators face ongoing exposure to styrene fumes.

- Electronics – ABS plastics are frequently used in electronic casings and components. Without sufficient ventilation, fumes can accumulate and increase respiratory risks.

- Labs – Research labs often use ABS in experiments and model-building, where safe, ventilated environments are essential to protect technicians.

- Dental – Dental technicians sometimes use ABS-based materials in modelling and prototyping. Read more about dental fume extraction.

By recognising where ABS printing risks are highest, businesses can implement effective extraction systems tailored to their environment, ensuring both compliance and operator safety. This is why workplaces in these sectors often rely on dedicated clean air systems like those developed at Purex.

How to identify poor air quality when printing with ABS

While some fumes are invisible, there are clear signs that your workspace may need better ventilation or fume extraction:

- Strong, lingering odours – ABS produces styrene vapours, which often have a sharp, plastic-like smell that doesn’t dissipate easily.

- Irritation symptoms – burning eyes, sore throat, headaches or dizziness can all be indicators of overexposure.

- Visible haze or particles – poorly ventilated rooms will inevitably end up with a mist or haze in the air made up of irritable particles.

- Reduced comfort – if the room feels stuffy or you notice difficulty breathing after long print runs, your indoor air quality could be compromised.

Spotting these signs early is key to protecting yourself. Installing a proper fume extraction system helps ensure the air is continuously filtered, keeping both your workspace and your health safe.

Can a 3D printer fume extractor help?

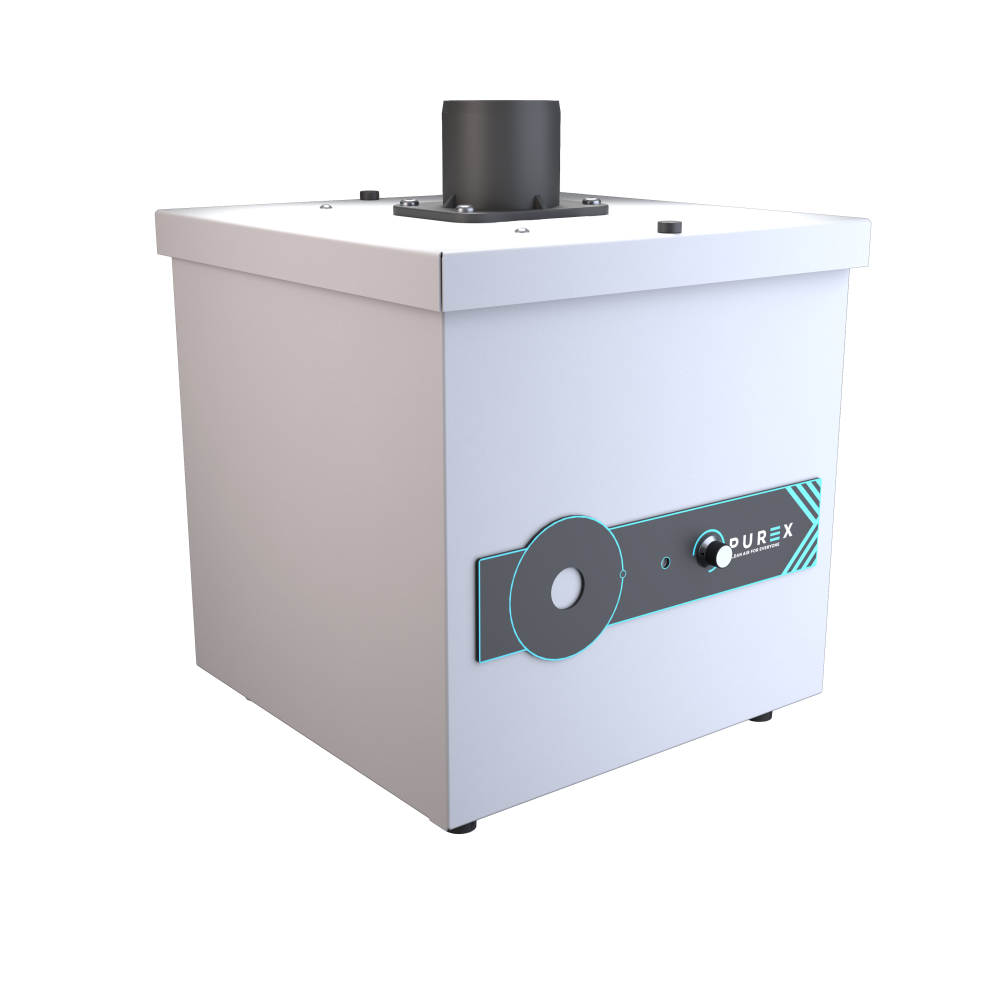

Though ABS filament fumes are generally not toxic, it is recommended that rooms which contain ABS processes or 3D printers should be ventilated well or contain a suitable fume extraction system, such as the Purex Cub3d.

There are many benefits of using an ABS fume extractor, such as adhering to Health and safety regulations, COSHH 2002 (Control of Substances Hazard to Health), which refers to the exposure of dust, harmful gases and fumes in the workplace as a key part of their regulations. Further benefits include:

- Employee wellbeing – removing unpleasant or harmful fumes within the work environment can avoid any potential health problems, producing better working conditions for employees.

- Environmental factors – filtering and extracting harmful fumes positively impacts not only employee health, but also the environment. Fumes that are only extracted and not filtered will affect the environment elsewhere, which is why the process of filtering is just as important.

- Less downtime – harmful fumes can also damage products and equipment in the work environment. This could then lead to considerable downtime when replacing the equipment or products.

Fume extractors for ABS Filaments

At Purex, our clean air systems are engineered to tackle UFPs and VOCs effectively with:

- High-efficiency HEPA + carbon filtration for dust and smell

- Flexible extraction options, including arms, booths and enclosures, all tailored to your workplace and processes

- On-going monitoring and maintenance to ensure your system is performing consistently

We pride ourselves on providing an unparalleled level of service and support – including our 24-hour technical support service, start-to-end projects and response times. Get in touch with our expert team today to find out more about ABS and 3D printing fume extractors. Alternatively, book a LEV Test with our team to ensure your fume extractor is compliant and operating as intended.

Improve Your Workspace Air Quality Today

Latest insights

-

The Dangers of Grinding Dust and Particulate Matter

Grinding, cutting, fettling, and surface preparation are essential steps across metalworking, fabrication, aerospace, automotive, plastics and ma... Read more -

The Dangers of Flux Fumes in Electronics Assembly

Flux is an essential material in electronics assembly, helping to clean metal surfaces and ensure reliable solder joints. However, when flux is heated... Read more -

5 Signs Your Fume Extraction System Isn’t Working Effectively

and maintaining productivity. When systems begin to fail, the signs may be subtle at first, but ignoring them can lead to dangero... Read more

How Purex can help

We provide an excellent level of service and support, including our 24-hour technical support service and start-to-end projects. Get in touch with our expert team today to find out more.