Why Is Fume Extraction Important For 3D Printing?

As the creativity of our world continues to develop – with different and exciting products designed each day – more and more companies are relying on the use of 3D printers and additive manufacturing for their work. Starting with a 3D model, 3D software then brings the model to life from a digital file using additive processes – thus creating products we see everywhere in our day-to-day lives.

As this has rapidly transformed into a production technology adopted by a large majority of companies, this has then led to an increase in discovering the unwanted side effects of additive manufacturing. Printing fumes contain ultra-particles alongside a wealth of other unwanted and harmful chemicals that can affect health, equipment and the environment.

That’s why we’ve put together this guide – highlighting the importance of fume extractor systems for 3D manufacturing. These systems work to protect employees, environments and products against the harmful particles which are produced as a by-product of 3D printing.

What is 3D printing?

3D printing refers to the process of using a three-dimensional digital model to create a physical object. The process generally works by laying down multiple thin layers of the same material – such as liquid, plastic, cement, or metal – in succession, and then fusing these together.

Examples of 3D printing products include:

- Musical instruments

- Dental products

- Film and television props

- Replication of fossils or ancient artefacts

- Consumer products e.g. footwear, furniture, eyewear

- Prosthetics

- … pretty much anything you can think of!

The art of 3D printing has become an industry in itself – which then has revolutionised additive manufacturing from the small-scale projects to large industrial ones. On the back of this revolution, 3D printing fumes are now becoming a concern to the companies within the industry.

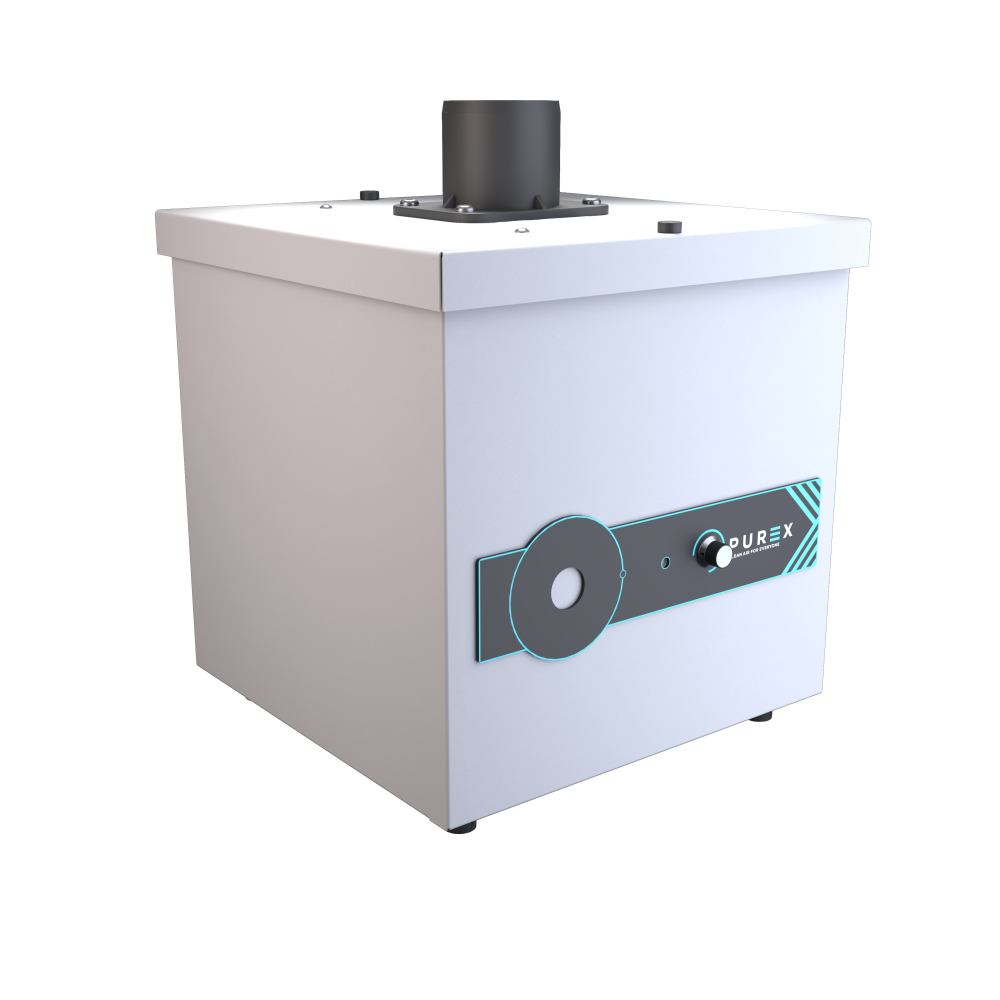

The solution? Cub3d fume extractor

To tackle the harmful chemicals and fumes that are exhibited in 3D manufacturing industries, Purex has designed the Cub3d machine – which fits over a wide range of 3D printers.

Providing efficient filtration of unwanted 3D printing fumes, this system is essential for companies that specialise in the additive manufacturing industry.

Some of the features of this revolutionary product include:

- Adjustable speed and hood – ensuring particles are extracted whilst the air is kept inside the printer, not compromising on the quality of the print

- Low capital and running costs – meaning there is no detrimental impact on energy bills

- Easy to install – with a quick installation process, this is simple to set up and quiet in operation

- Moveable – this system can be easily relocated to other areas if and when required

- Removes harmful gas – with activated carbon filtration

Learn more about the Cub3d fume extractor online today.

Benefits of using 3D printer fume extractors

So, why should you use a fume extractor system for your 3D printing industry?

Some of the main benefits are listed below:

- Employee wellbeing and health – by removing the fumes which are created within the work environment, a number of health problems can be avoided. These health conditions vary from mild annoyances – such as itchy skin or a runny nose – to more serious issues, such as occupational asthma and lung difficulties.

- Positive impact on the environment – extracting and filtering harmful fumes, would then not only improve employee health but also help the environment, too. If the fumes are only extracted and not filtered, these fumes can affect the environment elsewhere – which is why the filtering process is equally important.

- Reduction of downtime – harmful fumes are also likely to damage equipment or products in the work environment, which would then lead to significant downtime whilst replacing the equipment.

- Adherence to health and safety regulations – adhering to regulations set out by COSHH 2002 (Control of Substances Hazard to Health) – which regards the exposure of dust, harmful gases and fumes in the workplace as a key element of their regulations. Learn more about COSHH LEV regulations from our guide.

Find fume extractors for 3D printing companies from Purex

Want to know more about how fume extraction systems can benefit your 3D manufacturing company? Here at Purex, we’re proud to provide an unparalleled level of service and support – including our response times, start-to-end projects and 24-hour technical support service.

Get in touch with our helpful team today to find out more about 3D printer fume extractors. Alternatively, check your existing fume extraction system by booking an LEV Test with our team.

Latest insights

-

Purex International Ltd Bids Farewell To Its Former Headquarters

Today marks the end of an era for Purex International Ltd. After years of innovation, collaboration, and growth within these walls, we say goodbye to... Read more -

The Role of Spark Arrestors in Fume Extraction Systems

When working with fume extraction systems, safety isn’t just about filtering out harmful fumes; it’s also about fire prevention. One key f... Read more -

How Regular LEV Servicing Prevents Health Hazards

You might not think it, but regular LEV maintenance is a very important aspect in safeguarding for the health and safety of workers in environments wh... Read more

How Purex can help

We provide an excellent level of service and support, including our 24-hour technical support service and start-to-end projects. Get in touch with our expert team today to find out more.